Use digital checklists to implement the defined quality objectives in your company successfully.

- Examples Of Quality Objectives Manufacturing

- What Are Quality Objectives

- Quality Objectives Examples Manufacturing

- Quality Objectives Examples Manufacturing Services

- Top 20 Production Worker Resume Objective Examples You Can Apply. If you are seeking to work as a production worker and are making a resume or CV to present to employers, the objective statement must be carefully crafted to get the recruiter’s attention and gain an interview.

- A manufacturing KPI or metric is a well-defined measurement to monitor, analyze and optimize production processes regarding their quantity, quality as well as different cost aspects. They give manufacturers valuable business insights to meet their organizational goals.

A3 Report Template

Use a checklist for the A3 report to make it easier to gather the desired information, analyze the problem and plan the solution.

The manufacturer could break down this goal into two quality objectives: one involving improvement of timely delivery, and the other dealing with the issue of defective product. So, these objectives could read: To increase the rate of on-time delivery by 5% in the next 12 months. To decrease the rate of defective product shipped to customers.

Download templateISO 9001:2015 GAP Analysis Checklist

This gap analysis checklist will assist you to prepare for certification according to DIN EN ISO 9001:2015.

Download template8D Report Template

An 8D report template is used to document an understandable root-cause inspection based on the 8 Disciplines of Problem-Solving.

Download templateLumiform enables you to conduct digital inspections via app easier than ever before.

Get a kickstart with one of our +12000 ready-made and free checklists

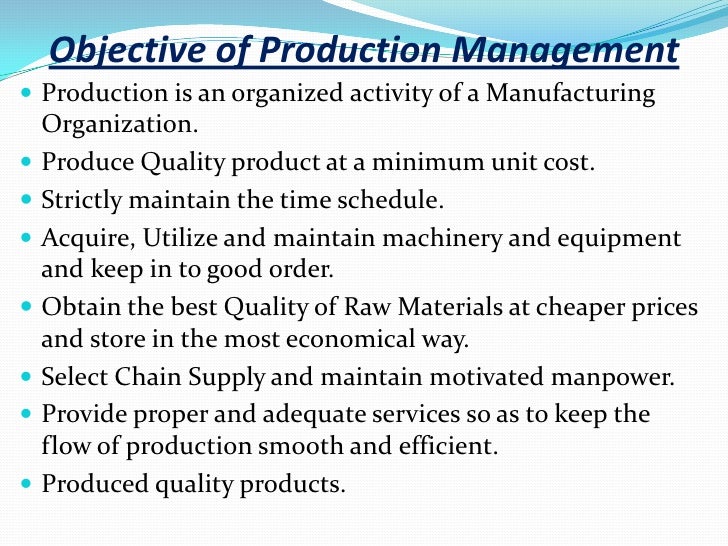

What are quality objectives?

Business flow should never stand still. Managers realize how important it is for an organization to be continuously improving. This can ensure the competitive strength of a firm on the market and motivate employees on honing their professional skills. What do quality objectives have to do with this?

Quality objectives are quality control goals that a company sets according to ISO 9001:2015 standards. These goals have to be SMART so that the employees could have a complete understanding of how and what they should to boost their organisational efficiency. The abbreviation stands for:

Specific. The item for improvement has to be clearly defined.

Measurable. The objective must be a quantifiable plan of action.

Achievable. The objective has to be realistic.

Examples Of Quality Objectives Manufacturing

Relevant. The goal must be related to the industry area relevant to the company.

Timely. The objective has to be done within a specific time frame.

This article deals with the following topics:

1. In which areas quality objectives are used

2. What to do if quality goals are not reached

3. The mobile application for tracking quality objectives

Related checklists

In which areas do we use quality objectives

It is true that for different industries we use different quality objectives. Therefore, it is difficult to name the objectives that would work perfectly fine for all the cases. However, there is one thing that all these goals have in common: they are all aimed at improving the level of customer satisfaction either directly or indirectly.

The examples of quality objectives with direct influence include:

- Delivery: Achieve X percent of deliveries done in <15 mins by September.

- Customer service: Maintain a customer satisfaction rate of X percent in winter months.

- Returns: Reduce the number of product returns by X percent in Q4.

The indirect influence can be seen within:

- Performance: Increase product performance to X days of use.

- Efficiency: Improve operational efficiency by X percent in comparison to 2019.

- Safety: Have zero safety incidents in the workplace or zero product defects.

What to do if quality targets are not reached ?

Every team will occasionally fail to achieve its quality goals. No one is safe from mistakes because humans are not machines that can be programmed for a specific action. However, if you are a considerate supervisor, you can minimize the number of failed goals by:

What Are Quality Objectives

- Documenting data

It will help to identify what went wrong and make the appropriate adjustments. Documentation should be thorough, and details such as the personnel, data, figures, incidents and other important information are recorded. - Evaluate resources against the quality objective

Look through the SMART components of the goal and check how realistic they areFor example, as for the A-aspect (Achievable), it should be reviewed how feasible this goal actually is. Does the company have enough resources and production capacity? There is a probability that it is not the fault of the workers that they cannot make the objectives work. - Have feedback sessions

Many managers and supervisors fail to make use of the individual talents of their team members, their opinions on the happening and just ask them how motivated they feel for a certain job activity. Managers should take time to listen to their employees and empower them to make the company better. - Perform a causal analysis to determine the reason for the failure

Numerous internal and external factors can contribute to failure. A root cause analysis can help to identify the main cause of failure. Corrective and preventive measures can then be formulated. - Create an A3 report to refine the approach

The A3 model is a problem-solving technique with the aim of identifying, understanding and solving problems in a business environment. It uses the PDCA (Plan-Do-Check-Act/Adjust) methodology, which is helpful for optimization to ultimately achieve quality goals.

Related app uses

The mobile application for tracking quality objectives

Once the S.M.A.R.T. quality objectives have been established, it is important to ensure that they are clearly communicated to the team. Additional measures, such as internal audits, help to ensure that all steps to achieve the quality objectives are followed. From the formulation of the quality goals to their communication and implementation, everything can be implemented more easily, quickly and efficiently with digital checklists.

- Collect data on the spot at any time with your phone or tablet via the app - online and offline.

- Use the collected data to formulate S.M.A.R.T. quality goals or to find the root cause of defects.

- Share completed quality goal templates immediately with teams and stakeholders to ensure immediate implementation and visibility.

- Customize our pre-built quality goal templates using our form builder or create your own to fit your business needs

- Assign corrective actions to team members instantly and track their completion in real-time

- Easily communicate updates and changes to quality goals through the app

- Extensive analytics help you uncover inefficient areas in your business faster to better achieve your quality goals

Related topics

Your contact for all questions concerning Quality Objectives

You have questions or would like to schedule a personal demo? We are happy to help you!

Quality assurance metrics are quality objectives. They mean the same thing. ISO 9001 standard requires that you establish quality objectives.

Quality Objectives Must Be

- measurable

- Relate to your business products

- documented

- reviewed

- tracked

StreamLiner is Project Management software that drives your team's Lean and Continuous Improvement activities.

StreamLiner

Quality Objectives Documentation

Your quality objective documentation should

- Tell specifically what you are measuring

- State how you collect the data.

- The frequency of the measurement

- Provide targeted goals

- State who is responsible for gathering the data

- State how they are recorded.

- State when they are reviewed

Quality Objective examples

Examples of Quality Objectives:

- Percent yield for a product

- Cycle time for a product.

- CpK for a given process characteristic

- CpK for a product characteristic

- Number of product returns

- Product returns parts per million.

- Corrective action cycle time

- Number of open corrective actions

- Number of audit action items.

- Sales Volume

- Net profit

This Data Analysis Video teaches you the basic tools for understanding, summarizing, and making future predictions with your collected data. Includes MS Excel templates.

Data Analysis Video

- inventory turns

- Number of key customers.

- installation time

- Number of preventive actions

- Quality Costs.

- Number of supplier rejects

- Key supplier lead times

- Number of data entry errors

- Rework costs.

- Defect costs.

- Number of processes out of control

Determining Quality Assurance Metrics

Select quality assurance metrics based on your business needs. The metrics need to make sense to your organization.

When determining metrics, select metrics that are global to the entire operation. Then select metrics that support those global metrics. Break the metrics down by department, process, organization function or product.

The metrics have to be agreed upon. A management committee determines the metrics. Senior managment communicates these metrics through out the company.

All employees should be able to identify the metrics. All employees should know how their work affect the metrics.

Make metric targets reasonable and challenging. Management provides the plans to achieve the targets. During the quality management review, review the metrics and document the plans to achieve the targets.

Some companies put the quality objectives within the quality assurance manual. I do not recommend this. Your customers do not need to see your quality objectives. In most cases these are confidential.

8D Manager Software with 8D, 9D, 5Y and 4M report generator. Your corrective action software for managing, measuring, and reporting issues.

8D Manager

More Info

ISO 9001 Overview and a Brief History of the Standard

An ISO 9001 overview and history of the standard. Discusses prior quality assurance management standards and the evolution of ISO 9001.

An ISO 9001 Definition and Information

Looking for ISO 9001 Definition? Review to see information and key elements. Quality Assurance Solutions will help you achieve certification.

Need ISO 9001 Auditor to Audit your Quality Assurance System?

Selecting a competent ISO 9001 Auditor is critical to registration. Assure your auditor fits well with your company and your Quality Assurance systems.

ISO 9001 2015 procedures

ISO 9001 2015 procedures that you need to implement for ISO 9001:2015 certification.

List of ISO 9001 Registrar

Here is a list of ISO 9001 Registrar. This list includes all possible Registrars for ISO 9001, TS 16949 and AS 9100.

Discusses Quality Assurance form and Quality Records

A Quality Assurance form is a Quality Record. Did you know these are mandatory for ISO 9001 registration?

Discusses Quality Program Management Review Requirements

Learn how to conduct a Quality Program Management Review which is necessary for ISO 9001 Certification.

Document Revision Control. Implement ISO 9001

A guide for Document Revision Control System. A total document control system is important for your Quality Assurance program.

ISO 9001 Checklist Audit for ISO 9001:2015

Download Today. Start your ISO 9001:2015 implementation. Use our ISO 9001 Checklist for gap analysis, internal audits, and implementing ISO 9001:2015. $49.00. Satisfaction guaranteed.

Quality Manual Examples and Quality Manual Sample

Download Quality Manual examples, sample, and templates. Discusses the requirements for your ISO 9001 and other Quality Manuals.

Using ISO 9001 Logo rules

If your looking for an ISO 9001 logo, review this page first!

ISO 9001 2015 QMS Implementation Tips

Implementing ISO 9001 2015 QMS Key Tips and Help

Building an Efficient QMS

Build an Efficient QMS. Key items to consisder when your are the QMS Manager.

Process Approach and ISO 9001:2015

Learn the Process Approach for ISO 9001:2015

ISO 9001 and other QMS Survival Stories

Review and Contribute your ISO 9001 Survival Stories. Teach others on ISO Audit pitfalls and tne ISO 9001 definition.

9001 ISO Training, The key clauses in ISO 9001:2015

9001 ISO Training and the key clauses in ISO 9001:2015. Review these clause by clause concerns for your ISO 9001 QMS.

QA Manual ISO 9001 2015

Download Today. User our QA Manual ISO 9001:2015 template for your quality management system.

ISO-9001-2015-QMS-Kit

Download Today. Use our comprehensive ISO 9001 2015 QMS Kit to establish your Quality Management System and meet ISO 9001:2015 requirements.

Quality Assurance Solutions

Robert Broughton

(805) 419-3344

USA